CUSTOM TILE PROCESS

I had a very clear idea of the tile I wanted in a powder room we were renovating. I wanted mixmatched b/w geometric tiles with exposed copper pipes.

While trying to source tile I got mad at an Italian tile importer. The tiles they were offering were too expensive and I didn't really care for their designs up close. So, I decided to make my own.

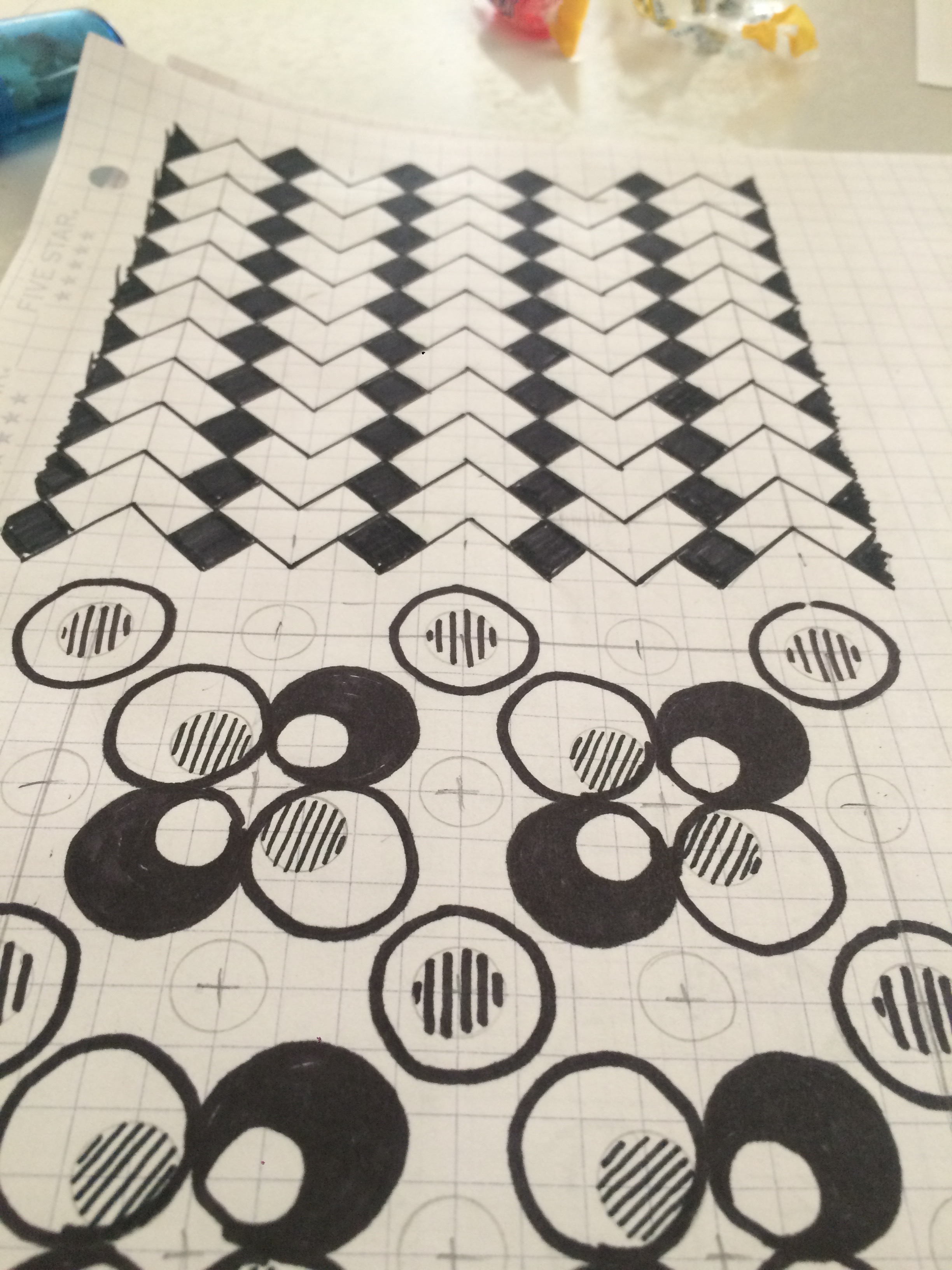

Hand Drawing

I worked on graph paper. Lots of graph paper.

Testing Glazes

This was all about getting the whites white and the blacks black.

Efficiency

I didn't want to burn 14 different screens so I had to figure out a way to get the most designs with the fewest screens. So I made a jig.

Screen Printing

I was able to get six designs on a screen.

Our krazy kiln

I fought through a lot of electrical issues with the kiln. I often had to fire each round twice just to get up to temperature.

Success

Crisp clean lines.

Quantity

I had just the amount I needed for the powder room.

OCD a little?

I created this paper guide for our tiler to follow... exactly.